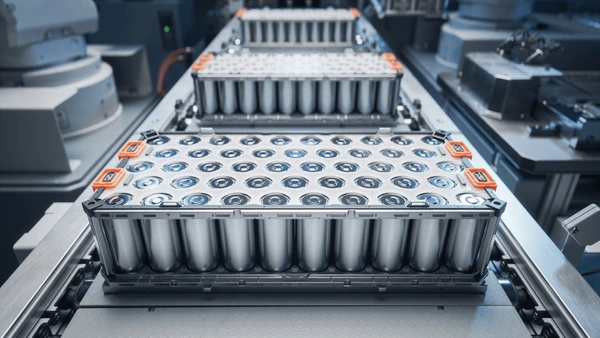

The backbone of the electric vehicle revolution is its battery, and India’s EV market in 2025 is witnessing a massive boom in EV battery manufacturing. With rising demand for electric scooters, cars, and buses, local and global players are investing heavily in India’s EV battery industry 2025.

In this blog, we’ll explore the Top EV battery manufacturers in India 2025, their technologies, investments, partnerships, and how they’re shaping the future of sustainable mobility. If you’re looking to understand the companies powering India’s EV transition, this detailed guide is your ultimate resource.

Tata Agratas – India’s Gigafactory Leader

The Tata Group, through Agratas Energy Storage Solutions, is leading the Indian EV battery race in 2025.

Gigafactory in Gujarat

Agratas is setting up a 20 GWh Gigafactory in Gujarat, one of India’s largest EV battery plants. The facility will supply advanced Lithium-Ion batteries to Tata Motors, Jaguar Land Rover, and other OEMs.

Technology & Vision

With a focus on LFP (Lithium Iron Phosphate) and NMC (Nickel Manganese Cobalt) chemistries, Tata Agratas is positioning itself as a global EV battery supplier. Its aim is not only to cater to domestic demand but also export to Europe and Asia.

Exide Industries – The Trusted Indian Battery Giant

Exide Industries, already a household name in lead-acid batteries, has stepped into the EV future with large-scale investments.

Exide Leclanché JV – Nexcharge

Through its joint venture Nexcharge with Swiss firm Leclanché, Exide is manufacturing advanced lithium-ion packs for EVs and energy storage. The Bengaluru plant has the capacity to produce 1.5 GWh annually, with future expansion in progress.

Why Exide Stands Out

Exide brings trust, distribution network, and after-sales service, making it one of the most reliable EV battery companies in India.

Amara Raja Batteries – Building the Future of Energy

Amara Raja, another Indian battery giant, is aggressively moving into the EV battery industry 2025.

Gigafactory in Telangana

The company is establishing a 16 GWh Lithium-Ion cell manufacturing plant in Telangana under its new brand Amara Raja Advanced Energy.

Focus on R&D and Sustainability

Amara Raja is investing in solid-state batteries, recycling technologies, and advanced chemistries, aiming to become a sustainable EV battery manufacturer with global competitiveness.

Reliance New Energy – Disrupting the EV Battery Space

Reliance Industries has entered the EV ecosystem with massive investments in green energy and batteries.

Reliance & Faradion Acquisition

Reliance acquired Faradion, a UK-based company specializing in sodium-ion batteries, offering a cheaper and safer alternative to lithium-ion.

India’s Largest Integrated Battery Plant

Reliance is building one of India’s largest battery plants (40 GWh) under its Dhirubhai Ambani Green Energy Giga Complex in Jamnagar, Gujarat. This move positions it among the top EV battery manufacturers in India 2025.

Ola Electric – EV Startup Turning Manufacturer

Ola Electric, India’s leading EV scooter maker, is now expanding into Top EV battery manufacturing.

Indigenous Battery Cell Production

In 2025, Ola inaugurated its cell manufacturing plant with plans to produce 20 GWh capacity by 2030. This vertical integration reduces dependence on imports and makes Ola a self-reliant EV battery maker.

Why Ola Matters

By producing its own cells, Ola Electric reduces costs for its scooters and potentially becomes a supplier to other EV makers.

Comparison Table – Top EV Battery Manufacturers in India 2025

| Manufacturer | Battery Tech | Capacity (2025) | Location | USP |

|---|---|---|---|---|

| Tata Agratas | LFP & NMC | 20 GWh | Gujarat | Gigafactory leader, global reach |

| Exide (Nexcharge) | Lithium-Ion | 1.5 GWh | Bengaluru | Trusted brand, JV with Leclanché |

| Amara Raja | Lithium-Ion, R&D | 16 GWh | Telangana | Solid-state & sustainability |

| Reliance New Energy | Sodium-Ion, Li-Ion | 40 GWh (planned) | Jamnagar, Gujarat | Largest integrated facility |

| Ola Electric | Lithium-Ion Cells | 5–20 GWh | Tamil Nadu (planned) | Indigenous battery manufacturing |

Pros & Cons of India’s EV Battery Industry

Cons

- Boosts local manufacturing & reduces import dependency.

- Encourages job creation and industrial growth.

- Pushes technology innovation (sodium-ion, solid-state).

- Makes EVs cheaper & accessible for the masses.

Pros

- High initial investment costs.

- Still dependent on raw material imports (lithium, cobalt).

- Battery recycling infrastructure is underdeveloped.

- Risk of overcapacity if EV adoption slows down.

Conclusion

Both Amara Raja Batteries and Exide Industries have firmly established themselves as Top EV battery manufacturers in India, driving the country’s transition toward electric mobility. Amara Raja stands out with its futuristic lithium-ion focus and international expansion, while Exide impresses with its strong legacy, vast distribution, and recent advancements in EV-ready battery solutions.

As India accelerates toward a sustainable future, the demand for reliable, durable, and high-performing EV batteries will continue to rise. This makes both companies vital players in shaping the future of the EV ecosystem. Whether you look at innovation, reliability, or market reach, Amara Raja and Exide are both leading contenders among the Top EV battery manufacturers that power India’s EV revolution.

In summary, if you’re exploring the Top EV battery manufacturers, Amara Raja and Exide should undoubtedly be on your radar for their contribution, innovation, and vision in the growing EV landscape.

👉 Want to stay updated on EV Future innovations? Explore more reviews, insights, and buyer’s guides on EV Insights today!

Trying to sign up for something? vipphregister.com might be the place. Registration process was easy enough, so far so good. vipphregister

Looking for some good affiliate programs, and dafabetaffiliates.net seems legit. Checking out what they’ve got to offer. Fingers crossed for a good partnership! Check them out here: dafabetaffiliates

Pingback: India EV Market 2026: $17 Billion Growth by Two-Wheelers

Yo! Played winme.com jogo online at Winmiibet the other day. Loads of fun, kept me entertained for hours! Definitely worth a shot if you’re looking for something new. More here: winme.com jogo online

Galera, tô afim de uns slots e me falaram da VZ66Slot. Os gráficos são bons? Tem bastante opção? Aceito dicas! Fica a dica: vz66slot

Alright, ss1game, gotta say, the graphics are pretty slick! Gameplay’s smooth too. Definitely a good option if you’re looking for something new. See for yourself: ss1game.

Yo, top646slot is where it’s at! These slots are FIRE! Seriously, I’ve been having some serious luck. Check them out if you want to try your hand: top646slot.

Uckiaapuestas, nice site. Love the variety of betting options they have. I’ll be honest, I lost a bit at first, but I’m coming back and I’m hopeful. Take a shot: uckiaapuestas.